Ashlar walling are typically more cost-effective than the quarried stone alternatives. The reason that artificial stone cladding is so much more cost effective than real stone cladding is that natural stone ashlar walling has to be sawn to very precise tolerances and then the surface needs to be smoothed to remove any production marks. It can then be laid with joints as small as 3mm and therefore appears almost seamless.

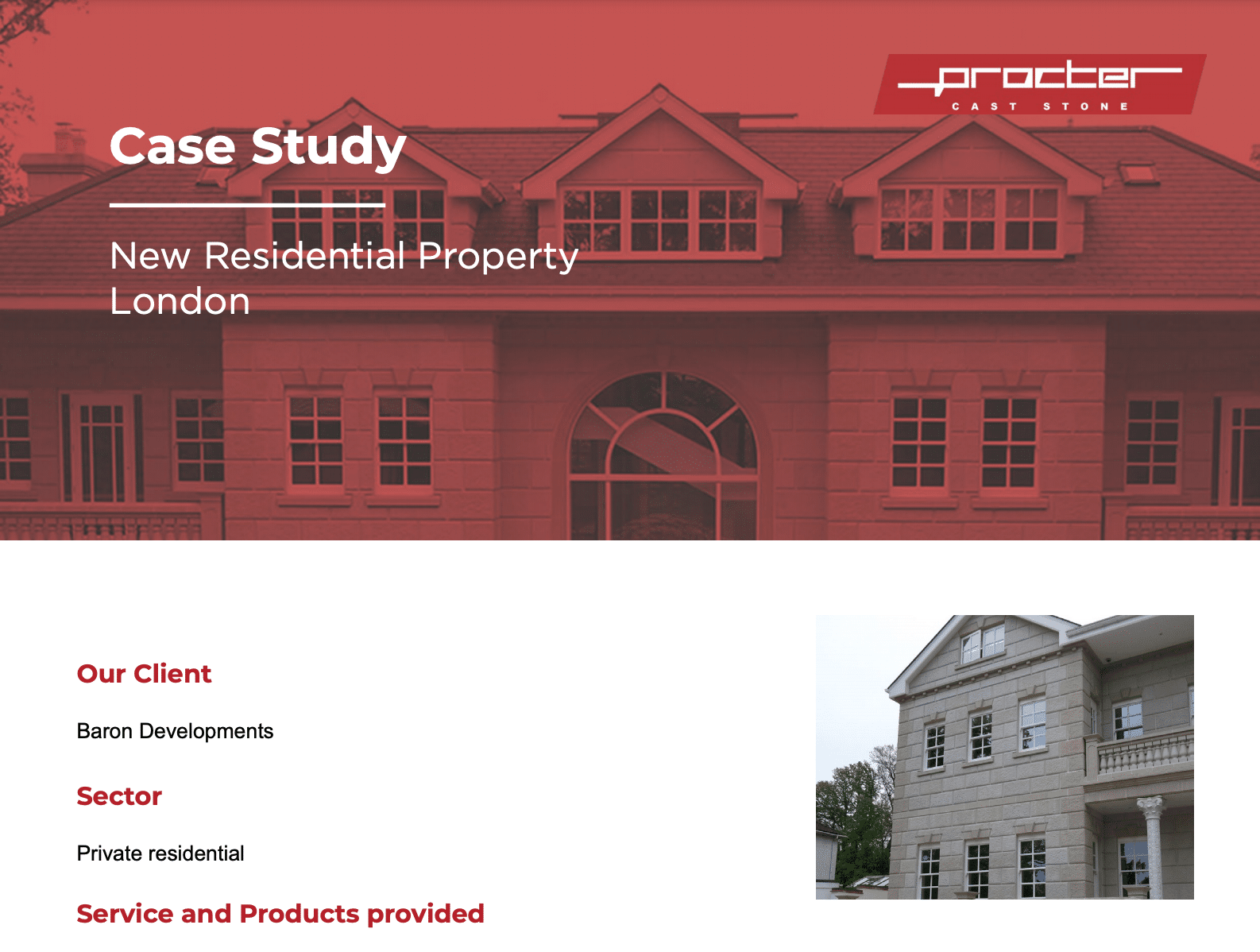

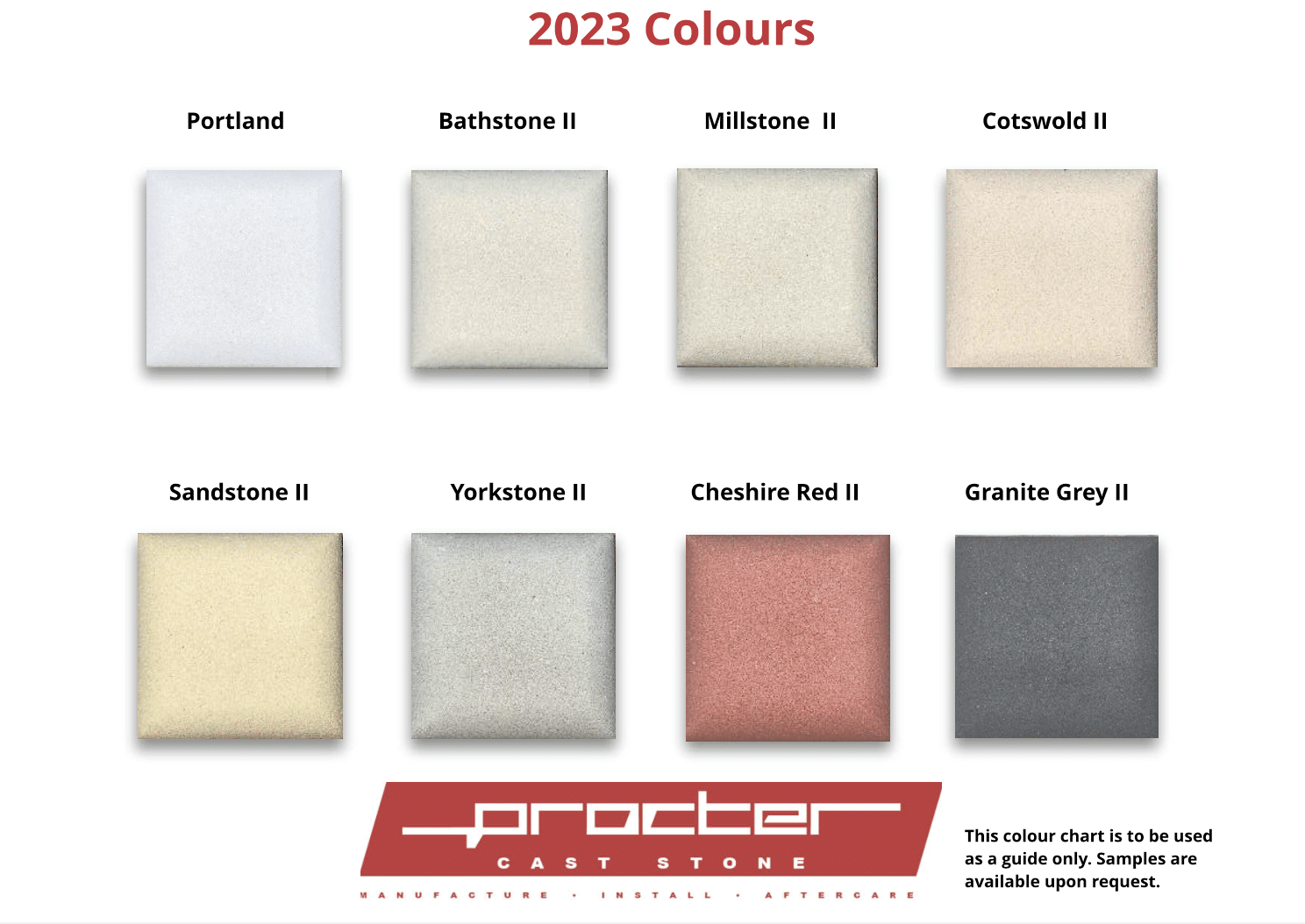

Because cast stone walling can be created in virtually any colour, it can be used in restoration projects in place of selected original stone cladding. This process is much more cost-effective than using natural stone cladding, and the end result will typically look every bit as good.

Consistency in size for artificial stone cladding

Producing a cast stone cladding, is far simpler and more accurate than natural stone because the exact dimensions needed are created once for the original mould. After that, every piece of reconstituted stone walling that comes out of the mould will be identical.Ashlar walling in artificial stone is more cost-effective

Creating an ashlar wall in artificial stone cladding rather than stone wall cladding is not only more cost-effective, but the end result will appear entirely convincing – so just as if the ashlar cladding was real stone.

At Procter Cast Stone we provide standard cast stone walling and cast stone ashlar walling but can also produce product in any design, texture, size and colour required.