Versatile Cast Stone products add architectural features

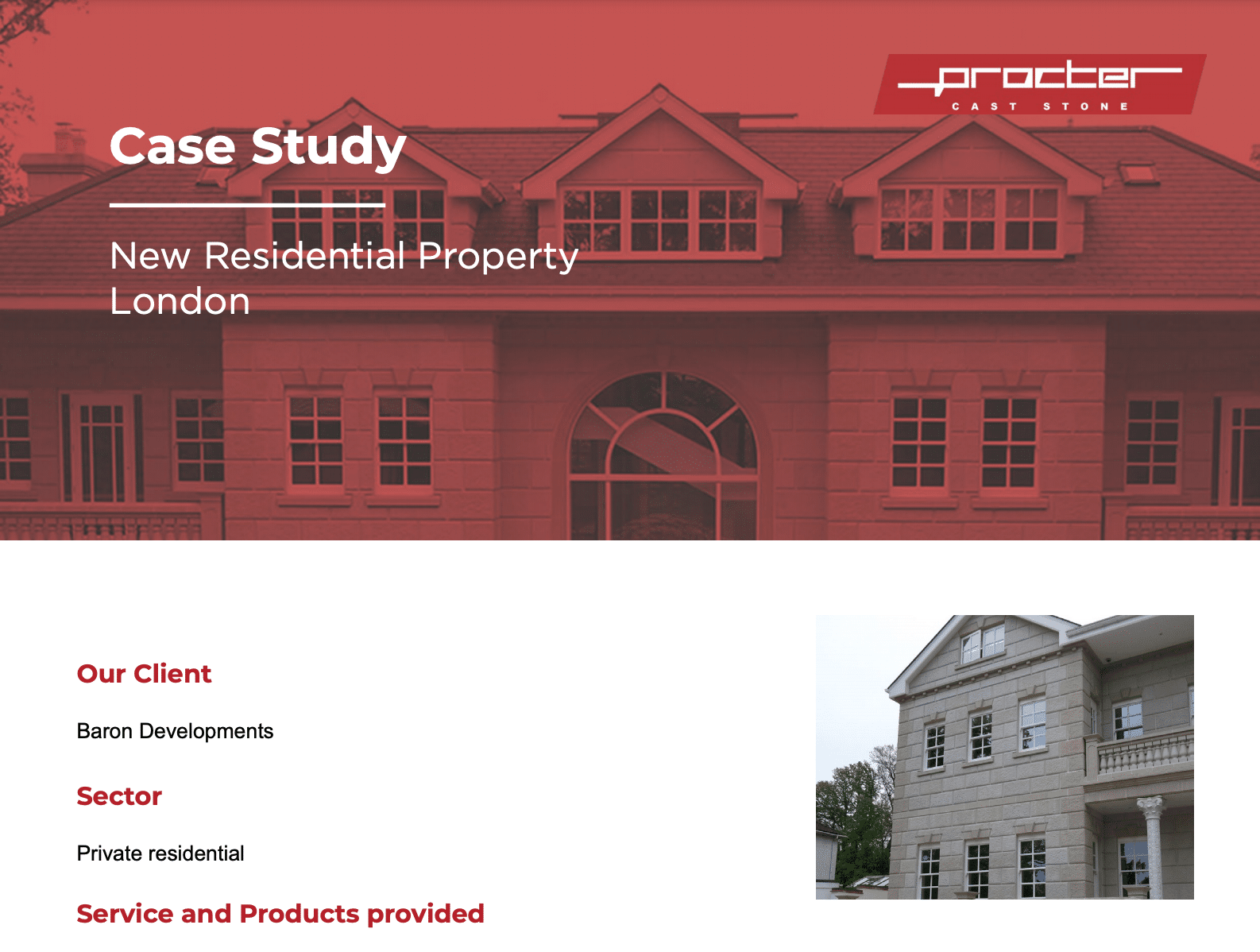

Cast Stone products from Procter enable architects to incorporate high-quality detail features such as cills, mullions, copings, quoins, columns, arches and pilasters can all be produced in a range of colours that closely match those of natural stone. In addition to its standard range, Procter is in a position to manufacture Cast Stone products to architects’ designs thanks to the company’s in-house mouldmaking facilities and team of skilled craftsmen.

Procter’s Cast Stone is characterised by a clean, sharp appearance that complements brickwork, natural stone, flint or rendering. The range of standard colours is designed to match those of natural stone, such as York stone, Bathstone, red sandstone and Portland stone. Procters can also match non standard colours to meet client`s special requirements. Over time, the Cast Stone weathers in the same way as natural stone. Almost any three-dimensional geometric form can be cast, allowing architects to design elegant curves as well as straight-edged features. Additional detail can also be incorporated into the surface, such as brick-effects or channels, and the edges of units can be square, bevelled or radiused.

Two of the most popular uses of Cast Stone are to add perceived value to housing developments and to incorporate styling features within prestigious projects. Elsewhere Cast Stone is used to mimic traditional details in infill developments or extensions to period properties, and to create internal features such as fireplace surrounds.

Where possible, all units are cast in a two-stage process. A facing mix provides the stone appearance on the exposed faces and a backing mix adds strength and forms a good bond with the reinforcement, where used. All manufacturing processes and independent tests are carried out generally in accordance with the requirements of BS 1217: 1997 (Specification for Cast Stone).

Procter has a tradition of excellence and craftsmanship that dates back over 260 years, though many of the design and manufacturing processes used to produce Cast Stone products are truly state-of-the-art. Procter look to develop long term relationships with customers by delivering high quality products and reliable personal service. In every project, large or small, a dedicated planner is assigned to oversee that every aspect of the work meets with the customer’s requirements.