The benefits of Choosing Cast Stone – Top Ten Reasons to Specify Cast Stone

Cast stone, or reconstituted stone as it is also called, is an attractive and very cost effective alternative to quarried stone. (This assumes that the quality is excellent and although our products certainly are, this can’t be said for all that are available in the market.)

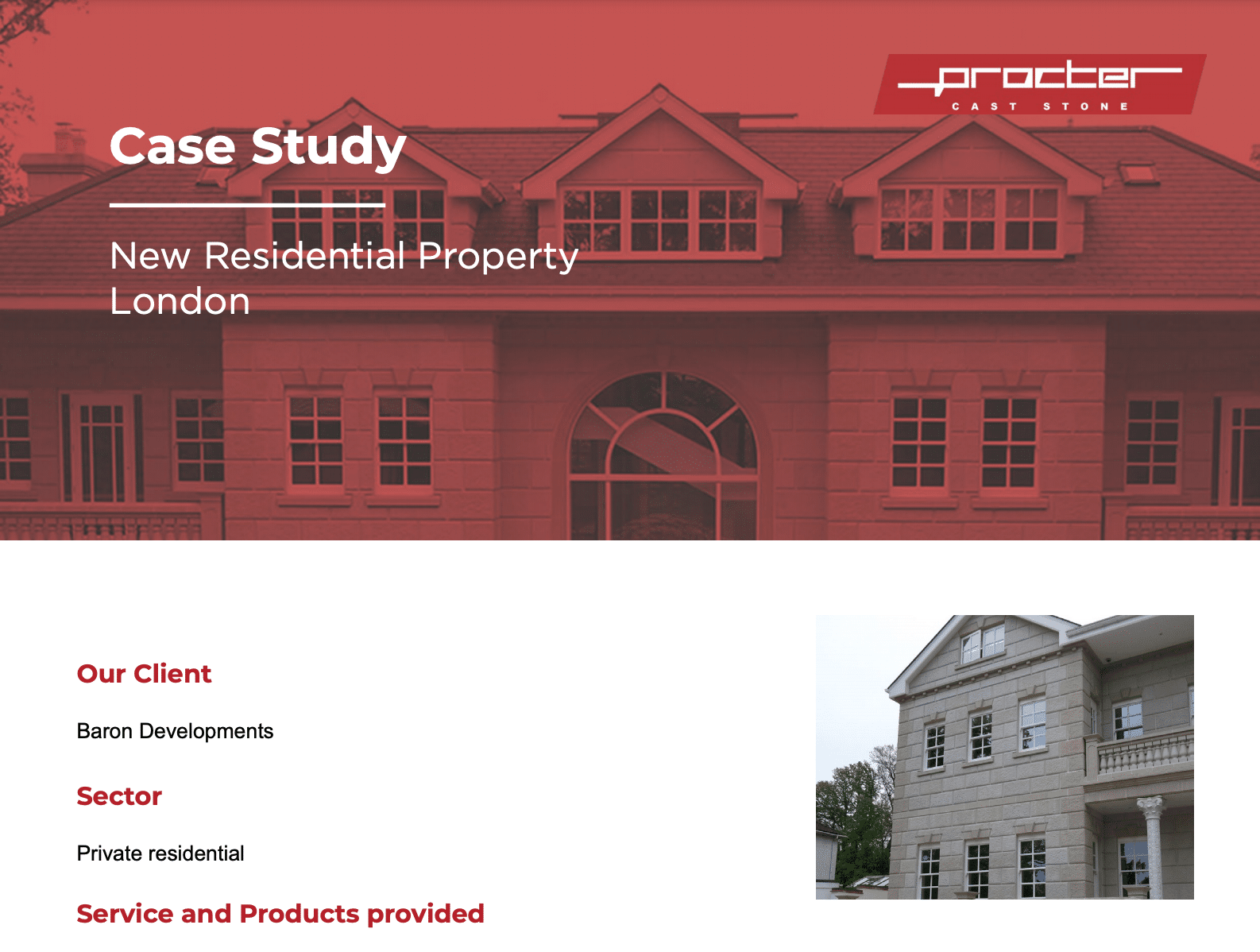

Architectural designs can be reproduced in cast stone to create a wide range of decorative features to enhance new buildings or match natural stonework for sympathetic restoration. Stone has traditionally been used to add character and style to prestigious properties, but today architects are using cast stone instead, achieving the same or better visual impact and with the added benefits of lower cost and reduced project risk.

- Freedom of Design – Almost any three-dimensional geometric form can be cast, allowing architects to design elegant curves as well as straight-edged features. Additional details can also be incorporated into the surface, such as brick effects or channels, and the edges of units can be square, bevelled or radiused. Furthermore, a variety of surface finishes and textures can be achieved. Cast stone can complement brickwork, natural stone, or rendering.

- Ease of Handling – While a degree of care is required for site handling of cast stone units – and reputable suppliers will provide Handling Instructions Download (or request your Handling Guideline Chart) – larger cast stone units can have features cast in place to facilitate mechanised lifting. This simplifies site handling and minimises the risk of damage to the units and injury to the operatives.

- Replication of existing units – moulds can be created to replicate existing natural stone features where a building is being restored or extended

- Replicate existing Features – Cast stone weathers in the same way as natural stone, there is no problem with installing new cast stone units alongside existing natural stone. Cast stone therefore be used during the refurbishment of older properties or for extensions or alterations.

- Colour Matching – Standard colours are available to match natural stone such as Bathstone, Red Sandstone or Portland stone, while non-standard colours can also be produced to meet a client’s specific requirements.

- Added value & Style to Prestigious Developments – Recent surveys have indicated that cast stone makes residential developments more attractive to prospective purchasers to the extent that they would be prepared to pay significantly more for a property with cast stone exterior features than they would for a comparable property without them. And because the cast stone features add almost nothing to the build cost, such as arches, balustrades, bullseyes, copings, cornices, porticos, steps and window and door surrounds can be selected from a catalogue or manufactured to an architect’s design. Cast stone is a very effective way to add style to prestigious developments.

- Cost effective and Efficient – Cast stone is extremely cost-effective in comparison with natural quarried stone, especially where repetitive work is concerned or where standard items are specified from a supplier’s catalogue.

- Efficiency / Save Time – Cast stone can be delivered to site on agreed schedules with relatively short lead times. In contrast, natural stone can have long and uncertain lead times.

- Quality consistency / Reduce Project Risk – because cast stone is manufactured in a factory environment in accordance with strict quality assurance procedures and under closely controlled conditions, a very consistent quality of colour and finish is assured – all of which helps to reduce project risk and keep schedules on target.

- A Free Guide to Cast Stone – Procter Cast Stone manufactures and supplies high-quality bespoke and standard cast stone products for projects throughout the UK, and has built up a reputation for exceptional standards of customer service. The company’s cast stone products are used for a very wide range of residential, retail, religious, self-build, ornamental and restoration applications. To assist in the process of specifying cast stone products, Procter has published an Architects’ Guide to Cast Stone, is available as a PDF file downloadable from Cast Stone Guides.

Advice from UKCSA October 2010 – “Cast Stone or Natural Stone?”

“A Viable Alternative”

Cast stone has been a familiar and much-used alternative to carved natural stone in the UK since Georgian times. It evokes a sense of timelessness which fits in with any form of massive construction.

As well as newbuild, cast stone is regularly used on sensitive conservation and refurbishment projects where natural stone is a predominant material. Its use includes the replacement or repair of natural stonework damaged by exposure or neglect.

Costs significantly less

Cast stone stands alongside natural stone as a building material in appearance and performance, yet it’s readily available and can cost up to a third of the price.

In many ways, cast stone is far better. It can beat natural stone on strength, moisture penetration, colour and textural consistency. Stratification is never a problem and it’s free from imperfections. Cast stone can weather like natural stone and it looks much the same.

For designers concerned with truth to materials, there’s another thing that today distinguishes cast stone. Often its colour is the result of choosing an aggregate with the appropriate inherent colour. So the final product can mirror the way natural stones are coloured.

And since cast stone details are based on centuries-tested stone details, they work first time.

Solid masonry

Cast stone can also take the form of ashlar masonry. These days natural stone is too expensive for solid masonry but it’s simple and economical to use cast stone ashlar blockwork – which not only satisfies the truth to construcition architectural argument but will perform in terms of bearing strength and weather in the same way as natural stone.

Concerns about carbon miles dog natural stone, which can be sourced from all over the world. In contrast, cast stone is made and distributed in the UK, often in localised markets, providing a minimal carbon footprint and maintaing UK employment. “